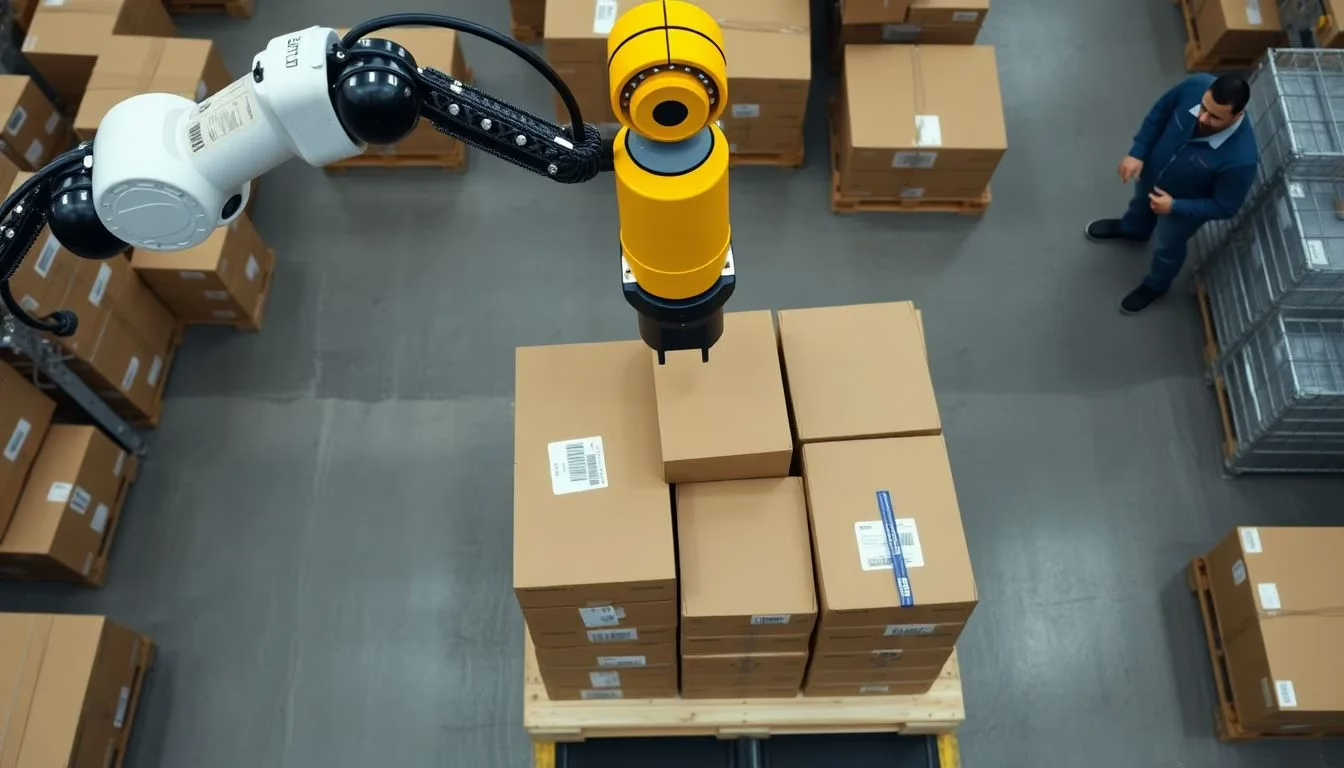

Automated pallet packing technology is transforming warehouses with innovative solutions like AmbiStack, which uses AI and robotic arms to efficiently stack items without human intervention. This technology reduces labor risks, increases efficiency, and enhances supply chain reliability, setting a new standard for logistics operations.

In the ever-evolving landscape of logistics and supply chain management, one of the most significant advancements in recent years is the development of automated pallet packing technology. This innovative solution, exemplified by Ambi Robotics’ AmbiStack, is revolutionizing the way warehouses operate by significantly reducing labor risks, increasing efficiency, and enhancing supply chain reliability.

The Need for Automation

Traditional pallet packing methods often involve manual labor, which can be time-consuming and prone to errors. Human workers are at risk of injury from repetitive motions and heavy lifting, making automation a crucial step towards safer and more efficient operations. Automated systems not only reduce the physical strain on workers but also minimize the risk of accidents and errors.

AmbiStack: The Pioneer

AmbiStack, developed by UC Berkeley spinout Ambi Robotics, is a prime example of this technological advancement. This system combines two critical warehouse operations—picking and stacking—into a single workflow. It features an industrial robotic arm mounted above a conveyor belt that moves along the X and Y axes. The arm uses suction cups to lift boxes from the conveyor belt and stack them into pallets with precision and speed1.

AI-Powered Efficiency

One of the most impressive features of AmbiStack is its AI technology. The system uses machine vision and artificial intelligence to identify items on the conveyor belt, acquire them, and stack them without prior knowledge of their size, position, or appearance. This advanced AI vision system, powered by foundation models and trained on over 200,000 hours of warehouse data, ensures that each item is analyzed, tracked, and picked with high accuracy1.

Reinforcement Learning

AmbiStack’s AI planning system employs reinforcement learning to reason about the most efficient stacking of unfamiliar items. This approach involves defining a reward function that incentivizes the robot to build stable, dense pallets. By adapting to real-world conditions on-the-fly, AmbiStack maximizes pallet and container utilization, making it an invaluable tool for logistics companies3.

Safety Features

Safety is a top priority in warehouse operations, and AmbiStack does not disappoint. The system includes light curtains and floor safety lasers to ensure a safe working environment. Access to pallet locations is restricted to the perimeter of the gantry workspace, preventing accidental interactions between humans and the robotic arm3.

Market Demand and Future Prospects

The global warehouse automation market is projected to surpass \$55 billion by 2030, driven by the need for efficiency and scalability in supply chain operations. AmbiStack is poised to capitalize on this trend, with pre-sales already open and the first deployments expected in mid-2025. The company plans to expand its manufacturing processes in early 2026 to meet the growing demand for this innovative technology1.

1. What is AmbiStack?

AmbiStack is an AI-powered palletizing system developed by Ambi Robotics that automates the process of stacking items onto pallets or into containers.

2. How does AmbiStack work?

AmbiStack uses a four-axis gantry robot with AI vision to identify and stack items without prior knowledge of their size, position, or appearance. It is trained on over 200,000 hours of warehouse data and employs reinforcement learning to optimize stacking efficiency1.

3. What are the safety features of AmbiStack?

AmbiStack includes light curtains and floor safety lasers to ensure a safe working environment. Access to pallet locations is restricted to the perimeter of the gantry workspace3.

4. What is the market demand for AmbiStack?

The global warehouse automation market is projected to surpass \$55 billion by 2030, driven by the need for efficiency and scalability in supply chain operations. AmbiStack is expected to capitalize on this trend with growing demand and expanding manufacturing processes1.

5. When can we expect the first deployments of AmbiStack?

The first deployments of AmbiStack are expected in mid-2025, with pre-sales already open and a select number of units available to early customers1.

The advent of automated pallet packing technology, exemplified by AmbiStack, marks a significant milestone in the evolution of logistics and supply chain management. By combining advanced AI and robotic arms, AmbiStack not only enhances efficiency and reduces labor risks but also sets a new standard for warehouse operations. As the demand for warehouse automation continues to grow, AmbiStack is poised to play a crucial role in shaping the future of logistics.

+ There are no comments

Add yours